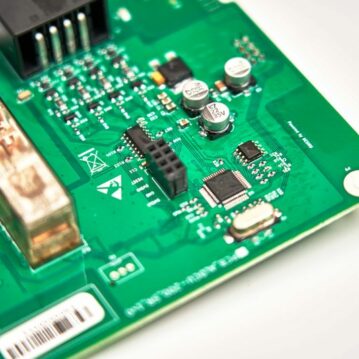

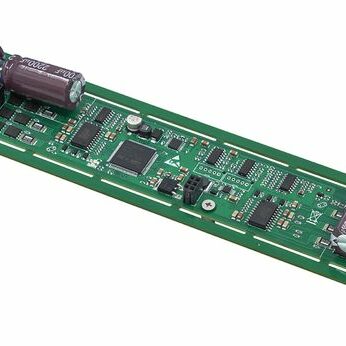

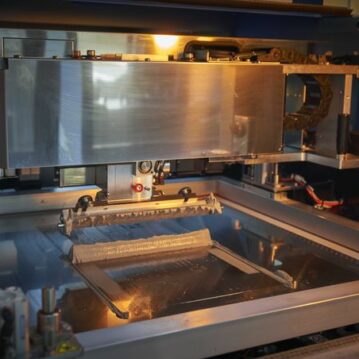

We provide EMS (Electronics Manufacturing Services) with our fully automated SMD assembly line and THT assembly line with Selective Soldering Technology

- 3D SPI (3D Solder Paste Inspection)

- 3D AOI (3D Automatic Optical Inspection)

- 3D X-Ray Inspection

- Selective Soldering Line

- PCBA Cleaning Machine

- Traceability along full production life starting from receiving a Purchase Order to finilize the shipment

- Nitrogen capable production (20 ppm)

- Automatic tray changer (18 Trays)

- Conformal Coating

- Mechanical Assembly

- Test (ICT, Functional) and Programming

Test and Programming Devices:

Ekibimiz; test senaryosu, çeŞitleri ve uygulama yöntemlerinin geliŞtirilmesinde uzmanlaŞmıŞtır.

We can design and produce test and programming devices that can be used to test every single board automatically and program the device’s firmware. These devices enables to detect production defects by minimizing human errors.

- Low-cost test fixture design

- Programming

- In-circuit Test (ICT)

- Functional Test (FT and Post-Production Test)

- Performance test (advanced functional test when needed)

- Ensuring product quality

- Decreasing delivery times by reducing test waiting times

- Reducing test costs

- Reducing the cost of programming MCUs on each board

- Increasing test capacity by the help of low-cost test solution that enables usage of multiple devices

- Efficient debugging helps on determining root causes of problems

- Achieving repeatability on test variations for every single board

- Continuous monitoring on quality

- By reducing the risk of low-quality products;

- Low rate of product failures at field

- Low cost for after-sales services

- Inmroved brand reputation that results with higher sales volume

- Increasing traceability with effective barcoding methods

Production Lines

Production is carried out on the basis of IPC standards.

“IPC-A-610, IPC-7711/7721, ANSI/ESD S20.20-2007, IPC J-STD-001, IPC-A-620, IPC-A-600”